TECHNICAL PRESENTATIONS

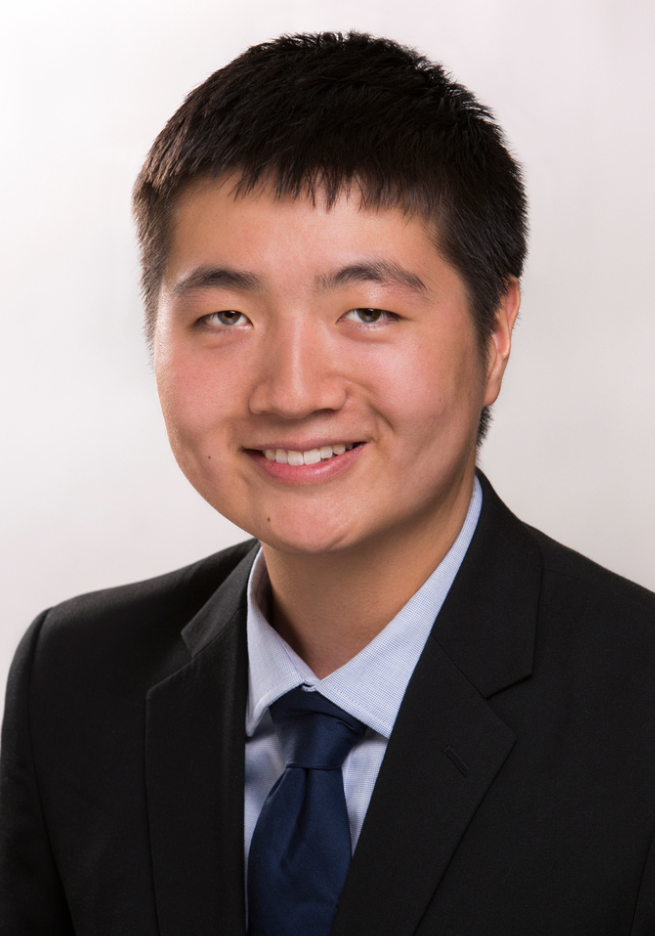

Akihiro Kawaguchi has been a chemist in the surfactant specialties R&D department of ADEKA Corporation for 6 years, based in Tokyo, Japan. His expertise is in development of additives for water-based paints and adhesives, with the goal of contributing to more environmentally friendly solutions. He obtained a master's degree in industrial chemistry from Tokyo University of Science, where he conducted research on synthesizing functional molecules, including stimuli-responsive catalysts.

This presentation introduces the effect of reactive surfactants with long ethylene oxide (EO) chains on the durability of water-based paint coatings. The durability of coatings is influenced not only by the inherent durability of the polymer but also by the dispersion of pigments. This study focuses on the correlation between the EO chain length in reactive surfactants, pigment dispersion, and the overall durability of coatings.

Emulsion films using reactive surfactants exhibit higher durability than those using non-reactive surfactants. However, this trend can be reversed in pigmented paint coatings due to reactive surfactants' lower pigment dispersion capability. Non-reactive surfactants contribute to pigment dispersion, while reactive surfactants, incorporated into the polymer, are less effective. This results in higher durability for non-reactive surfactants. The study found that longer EO chains enhance pigment dispersion through steric repulsion. Consequently, using reactive surfactants with long EO chains demonstrated significantly better durability than non-reactive surfactants.

Akihiro Kawaguchi

Chemist in the surfactant specialties R&D department of ADEKA Corporation

Effects of Reactive Surfactants with Long EO Chains on the Durability of Water-Based Paint Coatings

Amanda Schmotzer is a chemist at Wacker Chemical Corporation with four years of experience in architectural coatings. She earned her bachelor’s in chemistry from Siena Heights University and currently pursues a Masters in Polymer and Coatings Technology from Eastern Michigan University. When she isn't in the lab, you can find her reading, writing, and exploring her home state of Michigan with her husband and friends.

Perfluoro and Polyfluorinated-Alkyl Substances (PFAS) have been extensively utilized in various industries due to their exceptional ability to resist heat, oil, grease, and water. These properties make them ideal for applications such as water-resistant fabrics, non-stick cookware, stain-resistant carpets, firefighting foams, food packaging, and certain personal care products. Specifically, Fluorocarbon Surfactants (FCS) have been employed in waterborne coatings to enhance early "hot block" resistance. However, due to risk management concerns and impending regulations, there is a growing push to remove these chemicals from formulations. This shift presents a challenge for formulators who aim to adopt more sustainable additives without compromising performance. Our study explores the use of innovative phosphate ester wetting agents that offer improved early hot block resistance without the environmental drawbacks associated with fluorocarbon chemistry. These novel APE-free and low VOC specialty additives enhance colloidal stability, providing a blend of wetting, dispersing, and compatibility properties to water-based coatings. The study will present data on overall paint performance and examine the structure/property relationships that contribute to enhanced anti-blocking performance.

Amanda Schmotzer

Chemist, Wacker Chemical

Next-Generation Anti-Graffiti Coating: Single-Component, Durable, and Eco-Friendly

Anthony Gilbert is a Technical Marketing Manager for Lubrizol’s Hyperdispersants and Specialty Additives in North America. He has over 10 years of experience in the chemical industry with background in automotive color styling and color development, pigment and particle dispersions, and colloids research. He’s been with Lubrizol for 6 years, currently in Brecksville, Ohio. He earned a BS in Chemistry and a MS in Materials and Science and Engineering from Baldwin Wallace University and Case Western Reserve University respectively.

The latest developments in polymeric dispersants for polycyclic pigments enables reduced grind time, increased pigment loads, improved viscosity and stability, and excellent color properties. Organic pigments such as perylene and high-surface-area carbon black, especially in high-performance applications, can be difficult to adequately disperse and stabilize. Unique anchoring chemistry allows for strong adsorption to these pigment surfaces while finely optimized dispersant structure allows for efficient wetting, milling, and stabilization. These technologies can significantly aid in the breakup of agglomerated particles, in some cases even eliminating the need for traditional media milling. Pigment loads can be increased beyond traditional levels, even in nano-dispersion applications, improving overall cycle time without sacrificing viscosity or stability. Color properties including jetness, color strength, and transparency can be enhanced. This presentation will highlight these dispersant developments for difficult-to-disperse organic pigments and carbon blacks in aqueous coatings.

Anthony Gilbert

Technical Marketing Manager for Lubrizol’s Hyperdispersants and Specialty Additives in North America

Novel Polymeric Dispersants for Improved Dispersion of Polycyclic Pigments

Bruno Dário has 10 years of experience in the industry of surfactants and specialty chemicals. He has worked in Oil & Gas, Performance Products and Coatings, developing new products and applications for solvents and surfactants. Currently, he is a Technical Service & Development Scientist for Coatings and Performance Products at Indorama Ventures. He is responsible for the technical support for North American customers in the areas of surfactants for emulsion polymerization, coalescing agents, architectural and industrial coatings. Bruno earned his master’s degree in physical chemistry from University of São Paulo (Brazil) in 2021 focusing on the study of adsorption of surfactants. He earned his bachelor’s degree in Chemistry at the same Institution in 2015.

Bruno Dario

Research Scientist II

Innovative Strategies for Emulsifying Alkyd Resins

Bruce has a BA in chemistry from St. Olaf College, a MS in organic chemistry from The University of Minnesota at Duluth, a Ph.D. in organic chemistry from The University of Illinois at Chicago, and an MBA from The University of Michigan. He also performed research for a year in the organic chemistry department at Moscow State University in the Soviet Union. Following graduate school, he worked in technical, sales, marketing and business management positions at Wacker, Lubrizol, Michelman, and Euclid before joining CHT. Currently, he is a sales, business development and technical support manager for graphic arts and industrial coatings markets.

High Performance, Sustainable Wax-Based Surface Modifiers

There are increasing demands for higher performance, more sustainable coatings employing more natural materials with substantial health, safety, and environmental properties. To address those challenges raw material suppliers and coatings manufacturers are increasingly turning to water-based solutions that require efficient, environmentally friendly raw materials. The science behind key wax additive technologies leading to lower carbon footprints to meet these needs will be presented.

Innovative technologies will be presented that utilize unique waxes with a focus on performance, sustainability and reduced carbon footprint. These additives are used to provide coating advantages including water and oil repellency, early water resistance, block resistance, water beading, scratch and abrasion resistance, haptic properties, matting, and both slip and anti-slip performance. Novel coating additive features will be translated into specific advantages and benefits for coating formulators and end-users.

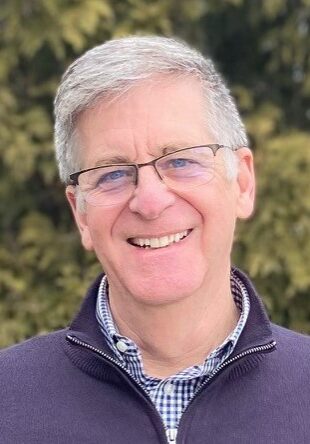

Bruce Berglund

Sales, Business Development & Technical Manager - Coatings & Graphic Arts

Architecture - Coatings - Concrete - Graphic Arts Solutions

High Performance, Sustainable Wax-Based Surface Modifiers

Chris has a diverse background in complex engineering and operational environments. After graduating from the U.S. Naval Academy with a Bachelor of Science in Naval Architecture, he earned a Master of Science in Engineering in Naval Architecture & Marine Engineering from the University of Michigan and subsequently served as a nuclear submarine officer. Following nine years of active service, Chris transitioned to the civilian workforce, taking on roles in heavy manufacturing and specialty chemical sectors.

Chris enjoys the challenges of problem-solving and the rigor of engineering practice but is particularly passionate about technical leadership and integrating the operations workforce with engineered solutions to develop reliable and maintainable systems. His extensive experience includes managing highly hazardous chemicals in production lines, mitigating risks associated with flammable liquids, vapors, and dusts, and planning, implementing, and ramping up capital projects.

He is also a registered Professional Engineer in the State of Maryland. Chris lives in Cleveland with his wife, Katie, their two children, and two Labrador Retrievers named Maui and Luna.

Effective planning of industrial maintenance and project work is essential for operational efficiency, minimizing downtime, and making the most of limited capital dollars - not to mention improved personnel safety and employee engagement.

Well-planned project work improves resource allocation and cost management, avoiding overstocking or underutilizing resources. While detailed planning may cost more up-front, planning done well reduces downstream risk to personnel, budgets, and timelines.

This presentation explores key aspects of effective maintenance planning, as well as cutting-edge techniques for project visualization and design evaluation, and the associated impacts on cost, schedule, and capability.

Chris Wozniak

Team Lead - US Operations, Element6 Solutions

Building Better Projects - Planning for Efficiency, Safety, and Engagement

Mr. Chojnowski is an intellectual property attorney that concentrates his practice in the chemical and material science arts. As Chairman of Howard & Howard’s IP Practice, Mr. Chojnowski oversees the filing and prosecution of thousands of patent applications each year. His practice includes global patent procurement, opinion preparation, freedom-to-practice issues, and portfolio managment. Prior to becoming an attorney, Mr. Chojnowski gained 7 years of experience as a research chemist in the coating industry. He holds a BS in chemistry, a MS in polymer and coating technology, and a juris doctorate degree.

Obtaining patent protection on coating formulations may be a challenge when the coating formulation is a combination of existing (i.e., “old”) raw materials. However, as coating formulators are well aware, developing coatings by combining existing raw materials in a new way can lead to synergistic interactions and yield an unexpectedly improved coating. The manner in which a newly developed coating formulation is presented to the United States Patent and Trademark Office (USPTO) can be critical in determining whether a patent will ultimately issue.

This presentation will detail the challenges of obtaining a patent on a coating formulation, including the USPTO’s typical rejections of patent applications directed at coating formulations. This presentation will also detail various strategies for obtaining a patent on a coating formulation with an emphasis on designing laboratory experiments and presenting experimental data to the USPTO. Finally, this presentation will also discuss the process of eventually compromising with the USPTO on a particular claim scope, and how strategically designed laboratory experiments have the potential to shape the compromise.

Cody Lindemulder

Sales, Business Development and Technical Support Manager

Architecture - Coatings - Concrete - Graphic Arts Solutions

Advancements in Surfactant-Free Hydrophobic Additives for Enhanced Hydrophobicity

Mr. Chojnowski is an intellectual property attorney that concentrates his practice in the chemical and material science arts. As Chairman of Howard & Howard’s IP Practice, Mr. Chojnowski oversees the filing and prosecution of thousands of patent applications each year. His practice includes global patent procurement, opinion preparation, freedom-to-practice issues, and portfolio managment. Prior to becoming an attorney, Mr. Chojnowski gained 7 years of experience as a research chemist in the coating industry. He holds a BS in chemistry, a MS in polymer and coating technology, and a juris doctorate degree.

Obtaining patent protection on coating formulations may be a challenge when the coating formulation is a combination of existing (i.e., “old”) raw materials. However, as coating formulators are well aware, developing coatings by combining existing raw materials in a new way can lead to synergistic interactions and yield an unexpectedly improved coating. The manner in which a newly developed coating formulation is presented to the United States Patent and Trademark Office (USPTO) can be critical in determining whether a patent will ultimately issue.

This presentation will detail the challenges of obtaining a patent on a coating formulation, including the USPTO’s typical rejections of patent applications directed at coating formulations. This presentation will also detail various strategies for obtaining a patent on a coating formulation with an emphasis on designing laboratory experiments and presenting experimental data to the USPTO. Finally, this presentation will also discuss the process of eventually compromising with the USPTO on a particular claim scope, and how strategically designed laboratory experiments have the potential to shape the compromise.

Daniel Chojnowski

Patent Attorney and Chairman of Howard & Howard’s IP Practice Group

Increasing the Likelihood of Obtaining Patent Protection on Coating Formulations

After completing his B.S. in Chemical Engineering at the University of Pittsburgh in 2018, Daniel Wang has spent the last 6 years as an industrial coatings chemist at Covestro, specializing in protective coatings. He also received a Master’s degree in Colloids, Polymers, and Surfaces at Carnegie Mellon in 2025. His expertise lies mostly in formulating polyisocyanate-reactive coatings, such as polyurethanes and polyaspartics, with an increasing focus on sustainability and the circular economy. His current projects involve formulating protective coatings with less impact on the environment, such as utilizing bio-based raw materials, reducing solvent emissions, or enhancing productivity. Besides coatings, Daniel likes to find new ways to incorporate his formulation skills into his cooking and plays drums for the Pittsburgh Steelers on the weekends.

Globally, the source of carbon reduction targets is evolving beyond process efficiency. Concepts such as embodied carbon and the circular economy are generating new opportunities for companies to not only reduce their carbon footprint, but also to drive value through sustainable innovation. For resin manufacturers, one contribution to carbon footprint reduction is to incorporate bio-based raw materials in their products that give formulators the opportunity to create more sustainable organic coatings. In this presentation, examples of both solvent-based and water-based high performance industrial coatings that utilize partially bio-based resins will be presented with test results suggesting that similar performance can be achieved with these resins compared to petroleum-based products on a multitude of properties.

Daniel Wang

Coatings Chemist at Covestro

Industrial Coating - US

Coatings & Adhesives - CA

Partially Bio-based Resins for High Performance Coatings: Performance Based on Chemistry

Ms. Hense serves as Technical Director of Stonebridge Coatings Laboratory where she and her team help companies assess the usefulness of new ideas, technologies and products for the paints and coatings industries. She has over 30 years of experience in a variety of industrial and OEM coatings technologies. She also has expertise in architectural paints, methods for analyzing coatings and physical methods of testing paints and coatings. Hense’s experience extends beyond coatings to include adhesives, inks and polymeric films. She holds a B.S. in Polymers and Coatings Technology and an M.S. in Polymer Chemistry from Eastern Michigan University.

With growing VOC regulations, restrictions on the use of fluorocarbons and demand for sustainability in the coatings industry, manufacturers are searching for ways to achieve their goals. Turning to bio-renewable raw materials is one way to get there. This presentation provides an overview of soy-based raw materials, including solvents, as an alternative to fluorocarbons to increase VOC compliance for a variety of coatings. Case studies include wood floor finishes, general metal finishes and industrial coatings applications. It is intended to provide formulators with additional tools necessary to develop more-sustainable, compliant coatings.

Debora Hense

Technical Director

Stonebridge Coatings Laboratory, Inc.

Achieving VOC Compliance Through the Use of Soy-Based Raw Materials as Alternatives to Fluorocarbons & Other Petroleum-Based Raw Materials

Dr. David Fairhurst is President of Colloid Consultants Ltd. a company that offers consulting services (from exploratory research projects through formulation and characterization to product production) in the field of cosmetics, personal care, and pharmaceutics and in all general areas of emulsion and dispersion technology. He is an internationally recognized expert in his field of expertise.

He was from 2016 to 2020, a member of the Opinion Leader Panel of the Economist Intelligence Unit which undertakes research on behalf of blue-chip companies around the world. To ensure that the reports reflect current thinking, Panel members are surveyed to capture fresh perspectives on a range of business, social and economic issues.

Formerly, Dr. Fairhurst was Executive Vice President of both Particle Sciences Inc. and NPR Healthcare Inc.

PSI was originally created (in 1994) as the R&D arm of sunSmart inc., a company that invented innovative ingredients for sun protection including Z-CoteÔ, a transparent microfine zinc oxide - voted by Forbes magazine as one of the top ten nanotechnology products of 2003 and SunCapsÔ (encapsulated sunscreens, vitamins, and organic actives).

At sunSmart, Dr. Fairhurst served as Senior Vice President and was directly involved (assisting CEO Dr. Mark Mitchnick) in discussions with the FDA to have zinc oxide included in the Final Monograph on Sunscreens, and to be designated as a Category I sunscreen active. PSI was spun-off following the sale of sunSmart assets to BASF in 1999.

At PSI, Dr. Fairhurst established and, for a time, managed a particle characterization laboratory to support formulation and production. The initial business focus of PSI was to manufacture, and sell, specialty raw materials to the cosmetics and the pharmaceutical industries. In addition, it offered custom formulation, surface modification and encapsulation services, aimed at controlled release and product stabilization. PSI evolved into a full-service CRO providing an integrated suite of drug development services (that utilized a variety of patented and proprietary delivery technologies) and was acquired by The LUBRIZOL Corporation (a Berkshire-Hathaway company) in 2015.

NPR was established (as an independent subsidiary of PSI) in 2000 to develop and market a line of skin-care products targeted specifically at dermatologists, plastic surgeons, and aestheticians. Many of the products utilized unique encapsulated actives manufactured through PSI. Dr. Fairhurst was involved in the formulation of skin, diaper, eye, and lip products (encompassing gels, lotions, creams, and ointments). NPR was sold to a private venture in 2007.

Dr. Fairhurst “retired” from corporate management of PSI in 2009 but continued to enjoy an emeritus position as Corporate Research Fellow until its sale in 2015.

David was also, for seven years (until December 2010) a consulting advisor on microbicide formulations (semisolids and vaginal rings) to the International Partnership for Microbicides, a PPP (created initially through the Rockefeller and Gates Foundations and the World Health Organization) whose mission is to prevent HIV transmission by accelerating the development and availability of safe and effective microbicides for use by women in developing countries.

In addition, he was for five years (until December 2008) an associate investigator in a consortium sponsored jointly by the Bill and Melinda Gates Foundation and The Welcome Trust (UK), and headed by Professor Robin Shattock (St. Georges Hospital Medical School and Imperial University, London). Funded as one of the Grand Challenges in Global Health, the consortium’s aim was to develop a “novel antigen design and delivery for sustained mucosal protection against HIV-1 infection”.

Dr. Fairhurst has over 60 years’ experience in the theory and practical applications of colloid and surface chemistry, as well as dispersion/emulsion technology.

His interests in surface and interfacial science began in 1960 when, as a laboratory assistant with Shell Research, U.K., he worked on problems of detergency in both aqueous and non-aqueous media under the supervision of E.J. Clayfield. His expertise expanded into the areas of gas and solution adsorption, as an undergraduate at Liverpool College of Technology, under the tutorship of Professor K.S.W. Sing (Brunel University and Exeter University). He graduated with a B.Sc. (Honours) in Applied Chemistry (and was awarded a British Association for the Advancement of Science Prize) and then, continued with postgraduate studies, at the Liverpool Polytechnic culminating, anno 1968, with the award of a Ph.D. in Physical Chemistry; his external viva voce examiner was Professor Ron Ottewill (Bristol University). His Ph.D. thesis, under the supervision of Professor A. L. Smith (Imperial College, London and University College, Oxford), was concerned with the studies of electrokinetic phenomena at the silver-halide solution interface. Pertinent to photographic processes, the work was supported by a grant from Ilford Ltd. During this period David built a device to measure the aggregation (flocculation and coagulation) of silver halide sols and he designed the prototype instrument that, later, was commercialized and sold as the Rank Bros. MK II Microelectrophoresis Apparatus. This development included a study of electrode polarization and Joule heating effects and how they impacted precise electrophoretic mobility measurements. He demonstrated how these effects could be minimized by the use of a thin walled microelectrophoresis cell and electrodes of Pt-black or combination Pd/Mo electrodes. Years later, these would be implemented in the design of cells for two other commercial zeta potential instruments – the PenKem Model 500/501 and the PenKem System3000 - and finally in the design of a cell to eliminate the problem of electro-osmosis (the Brookhaven ZetaPlus).

After obtaining his Ph.D. he was awarded a one-year Unilever Research Fellowship, at Unilever Research Laboratories, Port Sunlight, U.K. (with Dr. Colin Smart), to study the dispersion properties of builders in mixed water/solvent systems.

This was followed by two years as a Visiting Research Associate with Professors A. C. Zettlemoyer and F.J. Micale, at Lehigh University (U.S.A), to investigate dewatering phenomena in activated sludges for the U.S. Environmental Protection Agency. In addition, David worked on ink formulation at the National Printing Ink Research Institute (part of the Center for Surface and Coatings Research, Sinclair Laboratory) and taught post-graduate level (physical chemistry) courses in the Department of Chemistry.

Dr. Fairhurst returned to England in 1971 as a fully tenured Lecturer in Physical Chemistry at the Liverpool Polytechnic (now Liverpool John Moores University) where he taught, and tutored, in all aspects of physical chemistry. He established a Colloid and Surface Chemistry Research Laboratory and coordinated colloid/surface chemistry research and teaching within the Department of Chemistry and Biology. During his short tenure at Liverpool, he developed an interest in emulsion polymerization and, specifically, the production and characterization (particle sizing and zeta potential) of (emulsifier-free) polymer colloids and in the grafting of polymers and other macromolecules to surfaces; an emphasis being placed on carrier particulates for delivery of biologic actives. He was also responsible for overseeing the operation of the department Electron Microscopy Laboratory that provided analytical services to industry.

In 1974 Dr. Fairhurst joined, on an Open Competition Posting, the U.K. Chemical Defence Establishment (MOD) at Porton Down, Wiltshire. At CDE, he was responsible for Special Projects R&D, with an emphasis on protective systems against chemical warfare agents, for both the U.K. and NATO armed forces. A specific focus of studies concerned the topical and oral penetration of chemical toxins, and he authored the 1997 UK Position Paper on Chemical Defence. He also advised (on secondment) the sister Microbiological Research Establishment on aspects of the interfacial chemistry of biological surfaces and helped formulate both penetrative and barrier systems for biological agents. In addition, he was closely involved in the development of methods to monitor (and control) both contamination and decontamination of the land and water environments.

During this period Dr. Fairhurst continued his academic ties acting as an external thesis advisor at the Universities of Bristol and Aston and at Liverpool and Nottingham Polytechnics.

Dr. Fairhurst returned to the U.S.A. in 1981 to work, with Dr. E. D. Goddard, in the Surface Chemistry Skill Center of Union Carbide Corporation, Tarrytown, NY. As a senior member, he was responsible for the management of research programs concerned with various surface physiochemical aspects of emulsification fundamentals and emulsion polymerization, cosmetic and pharmaceutical processing aids, lithographic processes, antifoam formulation, asphalt/bitumen systems, and the characterization and application of novel surface-active compounds based on silicones. The work encompassed basic and exploratory research, product formulation and development. To this end he established in his laboratory (in collaboration with Dr. M. P. Aronson) a multi-angle laser light scattering system to measure the particle size of suspensions and emulsions - one of the first in the USA. In addition, he worked in close collaboration with, and support of, the Technical Services group of the Silicone and Urethane Intermediates Division. Here much emphasis was placed on the development of silicone fluids and elastomers for use in cosmetics and personal care and also specialty materials for use in medical devices and applications. While at UCC, he invented enabling silane-coating technology for personal care.

In 1984 David was appointed as the Technical Director of PenKem Inc., (Bedford Hills, NY), a fledgling manufacturer of scientific instruments for particle characterization. For four years, as the senior corporate technical officer, he was responsible for all instrument development, applications, customer support and worldwide sales. At PenKem he pioneered development of zeta potential instrumentation based on both laser light scattering and electro-acoustic spectroscopy and, in addition, particle size measurement based on acoustic attenuation spectroscopy - publishing (in 1988) one of the first papers on the technique. He also helped introduce a unique ultra-low (“zero”) shear rheometer designed to probe the structures of gels. During his tenure the company sales increased by five-fold and established PenKem as a recognized major commercial supplier.

Dr. Fairhurst was, for six years, a partner in Brookhaven Instruments Corporation, (Holtsville, NY) where he served as Vice President (Sales and Marketing) and Director of Applications. This afforded him much collaboration with major industrial, cosmetic, personal care and pharmaceutical companies. During this period, he introduced to the market two unique techniques for the determination of zeta potential; one based on streaming potential and the second using phase analysis light scattering. The latter technique was developed in specific response from the pharmaceutical industry for a technique to measure and characterize the stability of drugs dispersed in propellant fluids, as well as to be able to precisely measure biological surfaces, such as cells, in physiological milieu. He was also directly involved in the development of the disc centrifuge technique (in two distinct detection modes: X-ray and light) and also the use of laser/fiber optic-based back-scattering methods – both for particle size analysis. His efforts resulted in over a six-fold increase in sales and in BIC becoming a major international player in the supply of instrumentation for particle characterization. He left in 1994 to work full-time with sunSmart.

In 2005, he co-founded XiGo Nanotools Inc., and served as Executive Vice-President and Chief Technology Officer until his resignation in 2016. The first commercial product was a unique particle surface analyzer using nuclear magnetic resonance (NMR); a flow-through modification for QC monitoring purposes received the 2014 Most Innovative Product Award by Ben Franklin Technology Partners. In addition, XiGo developed (with funding from the International Partnership for Microbicides) a “Smart Applicator”, a device to aid in monitoring adherence to clinical trial protocol of vaginal microbicide gels.

Recently, as a consulting advisor to Mageleka, Inc., he has been helping develop two further instrumental advances using the magnetic resonance platform. The first measures liquid diffusion (useful for studying drug binding and protein aggregation) and which also provides a means to measure the droplet size of emulsions and foams – without dilution (the first such device of its kind). Development of the droplet size device also paves the way to interrogate biomaterials such as cells, providing entry into medical diagnostics. The second is an intrusion porosimetry device that uses water (or solvents) – not mercury – for use with macro- and meso-porous solid materials.

During his career Dr. Fairhurst has authored 25 Confidential Business Reports and Classified Government Documents and is entitled to 10 patents. In addition, he is credited with over 500 scientific papers, technical articles, book chapters and presentations at scientific meetings; his first paper was published in 1964 in the Transactions of the Faraday Society and the most recent in Colloid and Polymer Science (March 2023).

For twenty-five years he was an annual guest lecturer on courses, organized by the American Chemical Society and STF (Sweden), covering modern methods of particle size analysis, the application of zeta potential measurements to industrial problems, the fundamentals of emulsification, the dispersion of powders in liquids and the formulation of cosmetics and pharmaceuticals. And, over the course of his career, Dr. Fairhurst has also been an invited lecturer on a variety of annual courses concerned with similar topics organized by the University of Massachusetts (Professor R. Rowell), the University of Washington (Professor J. Berg), Lehigh University (Professor F. Fowkes and Professor Ned Heindel), the University of Bristol, UK (Professor B. Vincent), the University of New South Wales, Australia (Professor J. Roper), IBM (Dr. K. Mittal), Xerox (Dr. I. Morrison), the Fine Particle Society (Dr. T. Ariman), and the International Fine Particle Research Institute (Ing. N. de Jaeger). He has been an adjunct with Fairleigh Dickinson University (Masters in Cosmetic Science program) and served on the Scientific Advisory Board of MANTA Inc. from inception in 2014 until its acquisition by HORIBA Instruments in 2019. In 2021 he was invited to join the Scientific Advisory Board of SPOKES SCIENCES, a technology company that is developing innovative products to provide better, safer, and more reliable functional ingredients to foods and beverages that enhance the health and wellness of consumers.

In 2016 David celebrated a 50-year membership of the Royal Society of Chemistry and he remains a member of various other professional societies in both the U.S.A. and the U.K. Elected to Sigma Xi in 1970, he is also a Chartered Scientist (EU) and a Chartered Chemist (UK). In 2003 he received the Lester Conrad Memorial Award from the Australian Society of Cosmetic Chemists, for his work advancing the science of sun protection and in 2008 he was recognized by the American Chemical Society (NY Section) as Distinguished Scientist of the Year, in recognition of his contribution to the development of HIV-prevention options for women.

Low-field nuclear magnetic resonance (LF-NMR) relaxation has emerged as a transformative technique for analyzing complex solid-liquid and liquid-liquid systems, including suspensions and emulsions. Unlike traditional high-field NMR, LF-NMR employs compact, cost-effective bench-top devices such as the Mageleka MagnoMeter, offering superior relaxation time resolution while simplifying operation and minimizing training requirements.

LF-NMR relaxation excels in characterizing wetted surface areas, dispersion quality, and interfacial interactions in particulate suspensions. It provides quantitative insights into the adsorption behavior of surfactants, polymers, and additives, revealing the dynamics of competitive adsorption and wetting phenomena. Additionally, this non-invasive, non-destructive method enables repeatable analysis of stored samples, making it ideal for long-term stability studies.

The technology is particularly advantageous for quality control (QC), requiring minimal sample preparation and enabling rapid, accurate measurements without altering sample integrity. It has demonstrated utility in assessing polymer solubility, determining material equivalency, and optimizing formulations across research, development, and industrial production stages.

By bridging gaps left by traditional particle-sizing and zeta potential methods, LF-NMR relaxation offers an unparalleled ability to evaluate complex formulations with precision. Its application in coatings formulation delivers actionable data that enhances product consistency, accelerates R&D, and supports robust QC processes. This presentation will demonstrate the transformative potential of LF-NMR relaxation in advancing formulation science and improving industrial productivity.

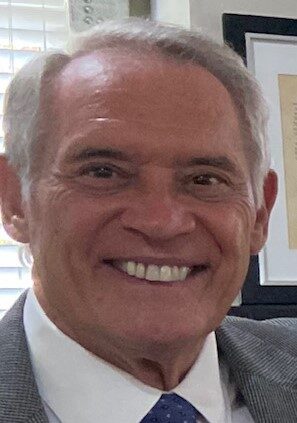

David Fairhurt

President Colloid Consultants Ltd.

Low-Field NMR Relaxation: A Versatile Tool for Coatings Formulation

A New Multifunctional Formulating Ingredient for High-Performance Industrial Coatings and Ink Applications:

The newest addition to the alkanolamine family, N,N-dimethyl-3 methoxypropyl-amine (DMMOPA) was specifically designed with several key properties valuable to formulators looking to improve manufacturing, application and dry-film performance in a variety of industrial paints and coatings applications. Several experimental demonstrations in various application areas highlight the versatility and multifunctionality of DMMOPA – from its use as a specialized additive in waterborne industrial formulations to a diluent catalyst in 2K PU coatings. When loaded as additive in 1K WB industrial coatings, the combination of pigment wetting effect, driven by its natural adsorption at pigment surface, together with its high volatility enabling low residual amine in the dry film, leads to improvements in chemical resistance, water resistance and stain resistance of the dry films. In the direct-to-metal applications that were investigated, this combination of properties supports enhanced anti-corrosion protection. In addition, with its wide solubility range and excellent compatibility with commonly used binder systems, DMMOPA can help formulators avoid the limitations of other conventional amines, including early water resistance, gloss or distinctness of image retention, and color stability.

Maximizing pigment and overall paint performance with multifunctional additives:

Developing high-performance formulations with minimal VOC emissions remains a challenge for formulators across a variety of paints and coatings applications. Alkanolamines, which are well-known for their exceptional ability to wet, grind, and stabilize a wide range of pigments, can help formulators achieve an optimal blend of other wetting and dispersing agents, while reducing the overall VOC profile of a formulation. With their innate affinity for pigment surfaces and the ability to substitute conventional counter ions of surfactants and dispersing agents, alkanolamine additives play an essential role in influencing, and improving various critical aspects of paint and dry-film performance, such as initial particle size distribution, storage stability, hiding power, corrosion protection, and color strength. The measurement of the natural chemisorption of several alkanolamines at the surface of various pigments enable better selection of the optimal structure versus pigment nature. Moreover, particle size distribution of waterborne pigment slurries supports the optimization of dispersing agent selection for higher dry film properties. This comprehensive investigation uncovers new ways to leverage the true potential of the unique characteristics of alkanolamines when interacting with TiO2, organic pigments, and anti-corrosion pigments, making them an indispensable formulating tool for developing and manufacturing the next generation of high-performance paints and coatings.

Dick Henderson

Sr. Technical Account Manager, Advancion Sciences

A New Multifunctional Formulating Ingredient for High-Performance Industrial Coatings and Ink Applications

Dr. Robert Sandoval, Technical Director at EPS, leads all polymer design activities for multiple CASE segments. He earned a B.S. in Chemical Engineering from Michigan Technological University in 2005 and a Ph.D. in Chemical Engineering from Northwestern University in 2010. He is a named inventor on 19 granted U.S. patents.

Dr. Dehui Han

Sr. Resin Innovation Manager at Anderson Development Company

Advances in GMA Acrylic Resins: Addressing New Challenge with Novel Approach

Dr. Kyle Flack is the Technical Manager for the Resins group within BASF's Dispersions, Resins, and Additives group based in Charlotte, NC. Kyle has been involved in the coatings industries for 13 years and in previous experience with BASF, he has served as technical services team leader for industrial coatings, R&D scientist for emulsions for industrial coatings and R&D scientist in formulation additives development. He holds a Ph.D. in Chemistry from the Georgia Institute of Technology.

This technical presentation delves into the comparative analysis of acrylic chemistries and alkyd emulsions, with a specific focus on their adhesion performance on challenging substrates. Our study aims to provide a comprehensive evaluation of these two chemistries when applied to pre-rusted and oily surfaces, which are commonly encountered in industrial environments.

We begin by detailing the experimental setup, including methodology for the preparation of pre-rusted and oily substrates, followed by the application of both acrylic and alkyd formulations. The presentation will cover the specific testing procedures, including adhesion tests and environmental exposures such as humidity and salt-spray performance.

Our results demonstrate the ability to use acrylic dispersions to provide similar adhesion properties expected from alkyd emulsions, highlighting the strengths and limitations of each. The findings will offer insights for industries seeking optimal coating solutions for substrates prone to rust and oil contamination.

Dr. Kyle Flack

Technical Manager for the Resins group within BASF's Dispersions, Resins, and Additives Group

Acrylic Dispersions: Performance Comparison with Alkyd Emulsions on Challenging Substrates

Dr. Robert Sandoval, Technical Director at EPS, leads all polymer design activities for multiple CASE segments. He earned a B.S. in Chemical Engineering from Michigan Technological University in 2005 and a Ph.D. in Chemical Engineering from Northwestern University in 2010. He is a named inventor on 19 granted U.S. patents.

Formulating water-based direct-to-metal (DTM) coatings presents unique challenges, as water can accelerate corrosion processes on metal surfaces. The choice of resin and additives is crucial in overcoming these challenges and achieving optimal performance. Additionally, increased regulatory scrutiny of solvent-borne coatings has driven a shift towards water-based systems with lower VOC content.

This study explores the impact of various formulation components on the performance of a waterborne DTM coating. We employed a 4-factor fractional factorial design of experiments (DOE) to assess the effects of coalescent, dispersant, neutralizing agent, and corrosion inhibitor on the coating's properties. The selected resin is a styrenated acrylic emulsion formulated at less than 100 g/L VOC. This resin offers high gloss, block resistance, and strong multi-substrate adhesion.

Our findings highlight the importance of selecting a resin designed for DTM applications that can provide corrosion and water resistance while maintaining formulation versatility. These results also demonstrate how the careful selection and combination of additives can significantly enhance the final performance of water-based DTM coatings, making them an excellent alternative to traditional solvent-borne systems.

Dr. Robert Sandoval

Technical Director at EPS

Exploring Resin and Formulation Factors in Low-VOC Waterborne Direct-To-Metal Coatings: Impacts on Corrosion and Adhesion

Romesh Kumar is new business development manager at SUDARSHAN Chemicals. His expertise includes colorants & applications, color measurement and other related subjects. He began his currier with American Hoechst Corporation and has been affiliated with pigment industry for over 44 years. He has made over 150 presentations including those at every organization related to Paint & Coatings and Societies of Plastics Engineers (SPE) in North America.

Educated at Laurentian University (Sudbury, Ontario), and Rensselaer Polytechnic Institute (Troy, NY), his current job functions include training colleagues and promoting innovative technologies. He teaches “Pigments for Coatings” educational programs for business professionals at University of Southern Mississippi (Hattiesburg), and North Dakota State University (Fargo).

His hobbies include hiking, biking, playing pickle ball and cheering his grandsons (Reed & Wyatt) at their hockey games in Massachusetts. He enjoys talking to strangers for new learnings.

Most organic pigments are based on carbon (non-renewable) driven raw materials. Now with improved technology, many of the high-performance polycyclic pigments (quinacridones) are synthesized from bio-based raw materials. These pigments have the same clean shades, and high performance necessary for brilliant shades, but with a much lower carbon footprint. Options for PFAS free pigments are there to meet all regulations.

Most inorganic pigments are metal oxides and have relatively low carbon footprint, almost ¼ compared to organic pigments. These have lower cost of use, and excellent fastness (solvent, chemical and weather resistance) properties. High opacity and good rheological behavior make inorganic pigments ideal candidates for blends with high chroma organic pigments to achieve specific shades. Such blends are sustainable, have higher performance & lower carbon footprint and of much lower cost of use.

Dissolver dispersible organic and inorganic pigments reduce manufacturing cost (much lower dispersion time). Pigment dispersions offer another option for quick and lower cost of manufacturing. Optimum pigment dispersions reduce the number of colorants necessary for both in-plant and POS formulations. In addition, quick color matching and durability & opacity options are possible, also meeting environmental standards.

Paint formulations with bio-based & dissolver dispersible organic pigments and inorganic pigments are sustainable, durable and cost effective. This approach leads to low carbon footprint and sustainable paint manufacturing. Furthermore, on quality first time, reduces paint waste.

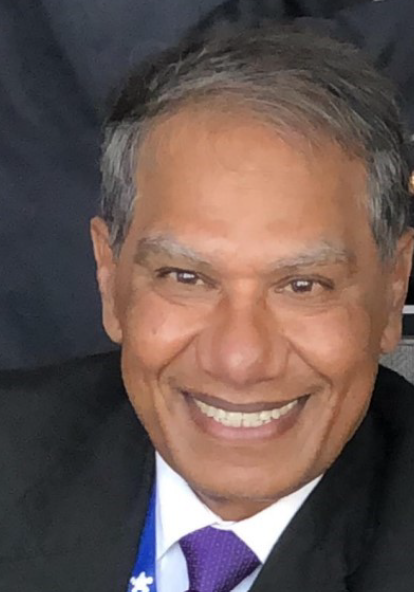

Dr. Romesh Kumar

New Business Development Manager - NorAm

Sustainability, Carbon Footprint, Bio-based Pigments for Durable Coatings

Frederick Cummings is a Technical Service Manager for Polyester Powder Coatings in the Americas at Synthomer Inc. Fred holds over 40 years of experience in the Powder Coating Industry, specializing in both coating powder formulation and polymer synthesis. Throughout his career, he has worked with prominent companies such as DuPont, Dow Chemical, Morton International, and Hexion. Fred's expertise is highlighted by several patents and publications in the field. His extensive background and innovative contributions have made him a valuable asset in advancing the technology and application of powder coatings.

Powder coatings offer numerous benefits over traditional liquid coatings, making them an important option in various industrial applications. This presentation will provide an introduction to powder coatings, focusing on their composition, application methods, and key advantages. We will explore the chemistry behind powder coatings and how different formulations can achieve specific performance characteristics such as special aesthetics, toughness, durability, and weather resistance. Additionally, we will discuss the coating process and the importance of selecting the right resin for different applications. We will also look at the latest advancements in powder coating technology, such as low-temperature curing and superdurable coatings, and how these innovations are shaping the future of the industry. This overview aims to enhance understanding of powder coatings and their diverse applications across multiple sectors.

Fred Cummings

Technical Service Manager for Polyester Powder Coatings in the Americas at Synthomer Inc.

Innovations in Powder Coatings: From Basics to Breakthroughs

Dr. Gautam Haldankar is a Technical Manager at Allnex. Prior, he has held various positions from scientist to technical service and business development manager. Earlier, he has worked with Sherwin-Williams, Akzo Nobel, and Nuplex Resins. He received his Ph.D. in Polymer Science from the University of Connecticut. He has over 30 years of experience in the resin and coating industry, with extensive knowledge of resin development and paint formulation. He has numerous publications and patents under his belt.

South Coast Air Quality Management District (SCAQMD) is the most progressive district to set rules for VOCs in North America to protect the environment and public health. Many other regions in the USA generally follow the SCAQMD regulations a few years later. SCAQMD is setting deadlines for elimination of parachlorobenzotrifluoride (PCBTF) and tert-Butyl acetate (TBAC) from coatings. Since PCBTF is widely used in the majority of low VOC coatings, it poses a big challenge for coatings manufacturers to meet the stringent regulations.

In this paper we briefly go over the regulations and deadlines set by SCAQMD. We describe various chemistries that are available to find solutions. These include solventborne 2K, waterborne 1K, waterborne 2K, polyurea, unsaturated polyester technology, radiation cure and Michael addition chemistry. After describing merits and deficiencies of each chemistry we give examples of a couple of chemistries by which it is feasible to meet the requirements set by SCAQMD. Many examples will be backed by coating performance data as well as accelerated weathering tests by Xenon weathering tester, crosslink density by DMTA and cure kinetics by IR spectroscopy. This information

Gautam Haldankar, Ph.D.

Technology Manager, Allnex

Clock is Ticking in South Coast California and Here are Options to Meet Regulations

Israel Skoff is a Technical Marketing Manager at Lubrizol Advanced Materials, Inc. with 12 years of service in industry. He received his Bachelor’s in Chemical Engineering and Master’s in Polymer Science and Polymer Engineering from the University of Akron. Prior to his role as a Technical Marketing Manager, he worked in the Technical Service labs and the New Product Development group creating and supporting Lubrizol’s line of polyurethane and acrylic dispersions.

Coatings for horizontal concrete surfaces such as concrete walkways or garage floors must hold up to very demanding conditions, not the least of which is withstanding vehicle and foot traffic. Other performance criteria include adhesion to a wide variety of concrete and masonry surfaces, chemical resistance and resistance to water whitening, especially with clear coatings. Currently, more labor intensive two-component (2K) coating systems are still widely used in the market to meet these high-performance demands, and are typically comprised of water-based, solvent-based, or 100% solids epoxy or urethane chemistries. Therefore, there is a high demand for getting comparable 2K performance with a one-component (1K), water-based system. The purpose of this work is to develop a 1k waterborne acrylic resin that has better tire stain and de-glossing resistances compared to traditional resins while maintaining low VOC (50g/L or less) for garage floor applications. The final product is also targeted to be ADH free, as this chemical has been classified as a skin sensitizer. To improve hot tire staining and imprinting resistance, various modifications to the polymer, including Tg and crosslinking density adjustment, were formulated and compared to existing products on the market.

Israel Skoff

Technical Marketing Manager at Lubrizol Advanced Materials, Inc. .

Improving Hot Tire Resistance with a 1K, Water-Based Acrylic Dispersion

Jana Shafer is the Product Manager for Pearls and Architectural Coatings for Americas at Vibrantz Technologies, the leading global supplier of colorants and tinting concepts for architectural and industrial coatings and plastics. With more than a decade of coatings experience, Shafer joined Vibrantz in 2024. Prior to Vibrantz, she worked as an R&D Chemist for Automotive Refinish at PPG, as well as a Technical Director and Product Manager for ChemMasters. She has two bachelor’s degrees in chemistry and biology from Baldwin Wallace University, and a Master of Business Administration from Baldwin Wallace University.

Sustainable innovation is transforming colorant tinting in the architectural waterborne coatings industry. Increasing demand for sustainability, driven by regulations and customer preferences, challenges traditional colorants to eliminate biocides, VOCs, and additives without compromising performance.

Vibrantz Technologies introduces a groundbreaking solution: the industry's first volumetrically dosed system of solid colorants. This innovation simplifies tinting, reduces machinery complexity and maintenance, eliminates purging cycles, and enhances tinting accuracy. With fewer mistints and minimal impact on paint properties, such as viscosity and blocking resistance, Vibrantz's solution offers superior sustainability, efficiency, and performance.

Integrated cloud technology further revolutionizes the industry, providing precise control over tinting processes. By addressing sustainability concerns and improving efficiency, this innovation sets a new standard in colorant tinting.

Jana Shafer

Product Manager for Pearls and Architectural Coatings for Americas at Vibrantz Technologies

Sustainable Innovation Revolutionizes Colorant Tinting

Jeffrey Kramer is the applications chemist for the Eco-Friendly Polyols division of Emery Oleochemicals with 5 years of formulations experience in the Polyurethanes CASE markets. Prior to Emery, he worked as an R&D engineer for Stockmeier Urethanes. Jeffrey has a Bachelors of science in chemical engineering from Louisiana State University (LSU) and earned his Masters of science in chemical engineering from the University of Twente (Netherlands) with his research in the sustainable process technology research group.

Emery Oleochemicals’ bio-based polyester polyols are beneficial building blocks for polyurethane concrete coating systems. Comparative studies demonstrate that these bio-based polyester polyols deliver the performance of their petrochemical counterparts, making them an ideal choice for a wide range of industrial and commercial applications. Designing specific polyester polyols with a range of hydroxyl values, viscosities, and functionalities creates a diverse toolbox for any coating application. This is highlighted by their performance characteristics, such as enhanced mechanical properties, excellent adhesion, and resistance to abrasion and weathering. These innovative polyols are derived from renewable feedstocks, aligning with the growing demand for environmentally friendly materials without compromising on performance. The ability to customize these polyols for specific coatings and different manufacturing constraints ensures optimal performance across diverse industries to achieve sustainability and high performance in coating solutions.

Jeffrey Kramer

Applications Chemist - Ecofriendly Polyols , Emery Oleochemicals

Bio-Based Polyols Transforming Polyurethane Coatings

John Du is the Global VP of Technical Marketing and Business Development for Patcham FZC headquartered the UAE and US. Patcham is a global manufacturer of specialty additives for the paint, coatings, inks, and plastics industries. Patcham manufactures, markets and sells its specialty additives globally through its staff and distribution network.

Prior to his affiliation with Patcham, John was the Technical Product Manager for the Paint Additives Division, and Business Development Manager of Paper Coating Additives of a dominant global specialty additives supplier. Before that, he spent many years accumulating his collective experiences in research, product development and technical service of compliant coatings for Automotive OEM, Refinish, General Industrial, Aluminum Extrusion, as well as formulation of pigment concentrates for various market applications.

He has held memberships and is an active supporter of the Cleveland, LA, Southern, New York, Pacific Northwest, Pittsburgh, and Past President of the New York Society for Coatings Technology.

He has presented numerous papers at technical conferences and symposiums during his career in the coatings industry. John’s expertise is in formulation, interfacial chemistry and the resolution of coating problems.

John received his Bachelor of Science in Chemistry from Westminster College and his M.Ed. from the University of Pittsburgh.

The pigment dispersion and stabilization stages are crucial to the successful manufacturing process of making paint. It requires the pigment stabilization mechanism be highly resistant to flocculation throughout the manufacturing, storage, application and solidification stages.

A new approach to the development of additives to enhance the dispersion and stabilization of pigments will be presented.

These new additives are soluble in a wide range of solvents, and exhibit compatibility in wide range of organic coating chemistries. High Molar Volume (HMV) uses highly branched structures to provide exceptional resistance to flocculation. These branched polymers occupy a greater volume than their linear counterparts and solubility in a wide range of solvents; while exhibiting a greater range of resin compatibility.

Also discussed will be the attributes of (HIA), Hyper Interactive Association polymers and their contribution to stability and compatibility.

Additionally, these specialty additives are able to disperse and stabilize the full range of pigment chemistries so that a single dispersant can now be used; simplifying inventory and reducing carrying costs.

John Du

Global VP of Technical Marketing and Business Development for Patcham FZC headquartered the UAE and US

New Technology for pigment Dispersion and stabilization

Kelly Carluccio is an Applications Chemist for the CCA group at MÜNZING North America. She has been with MÜNZING since 2019. Prior to her current role, she worked in the inks and coatings industries as a polymer R&D chemist, analytical chemist, and regulatory specialist, which provided a strong foundation in both technical and regulatory aspects of the field. She has extensive knowledge of additives for waterborne coatings and experience in applications testing and troubleshooting, product development, and technical customer support.

Recent updates in compliance guidelines have targeted the elimination of mineral oil, an effective, widely-used carrier for defoamer formulations. This presentation outlines the development of a new mineral oil-free and siloxane-free defoamer with broad regulatory compliance, along with the principles used to optimize defoaming potency while maintaining excellent wetting. The resulting defoamer has an estimated renewable bio-based content over 75%, while pushing the limits of performance possible in a mineral oil-free and siloxane-free defoamer.

Kelly Carluccio

Applications Chemist for the CCA group at MÜNZING North America

Defoamer Evolution: Advancing Mineral Oil-Free Defoamer Technology for Performance, Compliance, and Sustainability

Kevin Irving is a consultant for the International Zinc Association and is a graduate

of Harnischfeger Institute in Milwaukee. He has spent more than 28 years in the hot-dip

galvanizing industry.

Irving is a former board member for the American Galvanizing Association (AGA) and

was the vice president and general manager for AAA Galvanizing until its acquisition by

AZZ Metal Coatings in April 2008. He was the National Marketing Specialist for AZZ

Metal Coatings, former national board member for (CCAI) Chemical Coaters

Association International, and former vice chair of the NACE Committee on Hot-Dip

Galvanizing TEG 428X. He is also a Certified NACE Coating Inspector, and a member

of AREMA Committee 15, vice-chair and industry director for the Western Bridge

Preservation Partnership (WBPP

Steel corrosion is an expensive and dangerous problem worldwide that has devastating effects on infrastructure and other steel assets. It also consumes large portions of budgets for costs related to replacement, maintenance, and indirect costs to the public. A solution is necessary to address these concerns to maintain the material properties of the structures, safeguard the public, and increase the lifespan of metal structures.

This presentation will discuss Single Coat Inorganic and Organic Rich Coatings to aim at protecting steel from corrosion and minimizing maintenance over the life of the structure. The processes to apply these coatings is pretty much the same as all other IOZ’s. But with the OZ you can use a brush, roller or pretty much any spray gun including a wireless spray gun as well. Specifiers, asset owners, and transportation agencies will learn how they can use these coating options to protect and extend the life of their steel structures.

At the conclusion of the presentation, attendees will understand the science behind the protection offered by zinc coatings, including barrier and cathodic protection, and a discussion of the zinc patina. They will also have a chance to handle and inspect sample panels coated pieces with these two different zinc rich paints. In addition, the presenter will also show current case studies of bridges over 53 years old, and coatings at NASA from the 60s’ with no maintenance.

Kevin Irving

Consultant for International Zinc Association

How to Preserve Steel with Single Coat IOZ and OZ Coatings

Len Sweet is the Global Toxicology Manager at BYK USA Inc. He works closely with commercial and research teams to ensure the safe and intended use of products. Len provides expert guidance on toxicology, risk assessment, and sustainable chemistry. With a PhD, MPH, and MSc from the University of Michigan, Len brings a wealth of experience to his role. Prior to joining BYK, he held positions at The Lubrizol Corporation, ChemRisk, Albemarle, and Delphi.

The paint and coatings industry is facing unprecedented regulatory pressures, from emerging chemical restrictions to heightened sustainability demands. To stay competitive, manufacturers need reasonable and flexible approaches that dovetail with their core business strategies. In this presentation, we will delve into the latest regulatory developments affecting the industry, including in-depth analysis of chemicals like NMP and PFAS at both federal and state levels. We'll explore the intersections of regulatory compliance and sustainability, offering actionable strategies to help you: anticipate future regulatory trends to minimize compliance risks; develop best practices to avoid reactionary responses to unpredictable demands; and leverage industry relationships for regulatory process efficiencies.

Len Sweet

Global Toxicology Manager

BYK USA Inc.

Common Sense Strategies for Navigating Regulatory Complexity in the Paint and Coatings Industry

Perfluoro and Polyfluorinated-Alkyl Substances (PFAS) have been extensively utilized in various industries due to their exceptional ability to resist heat, oil, grease, and water. These properties make them ideal for applications such as water-resistant fabrics, non-stick cookware, stain-resistant carpets, firefighting foams, food packaging, and certain personal care products. Specifically, Fluorocarbon Surfactants (FCS) have been employed in waterborne coatings to enhance early "hot block" resistance. However, due to risk management concerns and impending regulations, there is a growing push to remove these chemicals from formulations. This shift presents a challenge for formulators who aim to adopt more sustainable additives without compromising performance. Our study explores the use of innovative phosphate ester wetting agents that offer improved early hot block resistance without the environmental drawbacks associated with fluorocarbon chemistry. These novel APE-free and low VOC specialty additives enhance colloidal stability, providing a blend of wetting, dispersing, and compatibility properties to water-based coatings. The study will present data on overall paint performance and examine the structure/property relationships that contribute to enhanced anti-blocking performance.

Dr. Lichang Zhou

Syensqo

Improving Early Hot Block Resistance without Using Fluorocarbon Surfactants in Water-Based Formulations

There are many types of rheology additives for waterborne formulations. Formulators may choose from classic bentonite clays or more sophisticated hectorites, from conventional cellulosic ethers to associative thickeners.

This presentation introduces a different type of rheology additive, based on an inorganic class of materials called inverted ribbon phyllosilicates (IRPs). IRPs combine benefits from other chemistries, without some of their drawbacks, for example:

- Ease of incorporation

- Insensitivity to pH or presence of ions

- Very fast shear thinning and recovery

- Excellent sag resistance

- Reduced in-can settling

- Reduced moisture absorption after cure

Crack bridging in thick films

Marcelo Herszenhaut

Business Development Manager BU Coating Solutions, LEHVOSS North America

Inverted ribbon phyllosilicates – a little-known family of rheology additives – and how they will change your formulations

Polyurethane coatings continue to evolve as a critical coating technology across the industrial coatings market. Due to their excellent durability, they are used in a wide range of industrial applications such as transportation coatings, as well as wood-based protective coatings. For many years, tin-based catalysts such as dibutyltin dilaurate (DBTDL) have commonly served as catalysts to promote the crosslinking of polyurethane coatings. Crosslinking adds benefits to polyurethane coatings that include fast dry times, high hardness, durability, abrasion resistance, and enhanced water and solvent resistance compared to many coating technologies.

While tin-based catalysts provide many benefits, they can negatively impact other performance properties such as pot life. Regulatory concerns have also been a challenge. In the European Union, products with more than 0.1% DBTDL are required to have appropriate labeling. They have classified DBTDL as a Mutagen and Reproductive toxicant. With these concerns in mind, ensuring that a catalyst achieves ideal performance characteristics and complies with tin regulations is crucial.

This presentation will address how tin-free catalyst technologies can help replace tin-based catalysts without compromising performance in polyurethane coatings. Furthermore, the data will highlight how common issues such as short pot life and slow drying times can be resolved, with retention of fit-for-purpose coatings performance in the applications targeted.

Michael Kramer

Milliken

Tin-Free Two-Component Polyurethane Catalysts for High-Performance Coating Applications with Tailored Cure Speed and Pot Life

- BS – Industrial Engineering – Iowa State University

- MS – Management – Central Michigan University

- MS – Finance / International – Walsh College

- 40 years Manufacturing / Plant Floor / Customer FIRST experience

UV LED coatings for pipe provide the following benefits:

- Drive process efficiencies

- Manufacturing an improved product – Exceeding Customer’s Needs

- Focus on Workplace Safety – EH&S

- Improving your Sustainability Footprint – Eliminating VOC's & HAP's

- Delivering improved ROI – Return on Investment

Several case studies will be provided.

Michael Kelly

Chief Customer Officer at Allied UV

Eliminate VOCs & reduce your energy costs with UV LED Coatings Technology

Born and raised in Montreal, Mike now lives in the Houston area. He has 38 years of coatings formulation experience, 18 years with coatings companies and 20 years with raw material suppliers. He is currently Technical Service and Development Manager, for Indorama Ventures: Indovinya. He has degrees in Analytical Chemistry and Environmental Sciences, as well as a MBA. Mike is Past President of The Detroit Society for Coatings Technology and the Piedmont Society for Coatings Technology and served on the board of The Chicago Society for Coatings Technology. He writes the “Formulating with Mike” column each month in PCI Magazine.

The selection of wetting and dispersing agents in pigment concentrate formulations is a non-trivial task. The vast array of available products and technologies, coupled with a frequent lack of adequate technical information, makes the formulator’s job extensive, intricate, time-consuming, and inefficient due the lack of rationalization in the use of these additives. The present study aims to demonstrate how the use, development, and implementation of physicochemical methodologies, combined with digital tools and high throughput screening, can generate highly useful data for formulators in the additive selection and formula optimization process, making it faster, smarter, and more efficient. The first and most comprehensive part of the work illustrates how physicochemical techniques and parameters applied to surfactants can be utilized in the selection of wetting and dispersing agents. The second part of the work is focused on the development of a method to create adsorption isotherms and on their use. This data is extremely valuable as it allows for comparisons between additives from different technologies even when the chemical structure is unknown. The final part of the work aims to apply Hansen solubility parameters (HSP) to evaluate the compatibility of wetting or dispersing agents with pigments. The current focus is on using high throughput screening to determine the HSP values of a variety of wetting and dispersing agents – such as surfactants and polymerics with or without charges. The last goal of the work is to provide initial data on the HSP parameters determination and compatibility simulations to then correlate with experimental performance data of pigment concentrates.

Mike Praw

The use of simulation tools and physicochemical properties to guide the selection of additives

Michelle Bauer is a Scientist at ICL where she has spent nine years focused on new product

development and technical service support of the Halox product line. Michelle possesses a

Bachelor of Arts degree in Biology from Augustana College. She has accrued over 20 years of

coatings industry experience, successfully commercializing additives and consumer coatings.

She previously held positions in quality management and product development for Valspar and

Ace Hardware Paint Division and is an active board member of the Chicago Society for

Coatings Technology.

Corrosion inhibitors are essential for protecting metal surfaces in various coating applications. Conventional inorganic inhibitors are derived from metallic salts that passivate the corrosion cell. Many inorganic corrosion inhibitors contain toxic heavy-metals that pose significant environmental and health risks. For example, the industry has moved away from the use of lead in most progressive countries. Chromates are another regulatory target that is being eliminated in many applications. Other heavy-metals, such as zinc and barium, are still widely used, but are under increased regulatory pressure in recent years. Coatings developers are looking for eco-friendly alternatives to provide the sample performance benefits.

Organic corrosion inhibitors are sustainable alternatives to heavy metal-based additives. They can be used to enhance performance of a current inhibitor package or relied on to replace toxic materials. Organic inhibitors provide an alternative mechanism for corrosion inhibition, which can reduce or eliminate heavy-metal use. They can also be used to synergistically enhance performance of the current corrosion inhibitor package when regulatory constraints are not eminent. A review of mechanisms by which organic inhibitors function will be provided. Case studies will highlight the factors that influence their effectiveness in diverse applications, including chemical structure, resin compatibility and use level.

Michelle Bauer

Future-Proofing Corrosion Control

This presentation highlights transformative innovations and key milestones in the paints and coatings industry, focusing on the interplay of technology, performance, and environmental considerations. It traces the industry's evolution from PPG's pioneering introduction of cathodic epoxy electrocoats in 1961 to the iconic "wet look" base coat/clear coat technology of the 1970s. Advanced cross-linking technologies, such as melamine polyester and aliphatic urethane systems, will be examined alongside modern application methods, including bell and reciprocator paint guns.

As coating resins near performance limits, the need for enhanced UV stabilizers becomes critical. This session will explore the development and application of innovative solutions like Ciba’s Benzotriazoles and HALS, which synergistically improve weathering durability in coatings, plastics, and other materials. Industry challenges, including bioaccumulation concerns, will also be addressed. Additionally, formulation techniques designed to optimize stabilizer effectiveness while reducing usage will be discussed, offering a balanced approach to performance and sustainability.

Professionals attending this session will gain valuable insights into the historical trajectory, current advancements, and future directions of the paints and coatings industry, making it an essential event for staying at the forefront of innovation.

Mike Pinchok

Sr. Technical Sales Account Manager at Mayzo

From Coatings History to Modern Advancements: The Journey Toward Stabilizer Innovation

I am the sales Director in coating and packaging for Mitsui Chemicals America. I have a PhD in Chemistry from the City University of New York in 2005. I was teaching at City College of New York between 2000-2005. I worked about 10 years in Research & Development at Hercules/Ashland Chemicals. After that I worked as a marketing manager with Lubrizol and Arkema for 6 years leading R&D team to develop market pull products.

Mitsui Specialty Chemicals introduces a dual portfolio of innovative polyurethane dispersions (PUD) and unique chemical wax dispersions, tailored to address the challenges of modern coatings. This presentation highlights the versatility of our PUDs, offering excellent adhesion to metal and plastic substrates, along with superior hardness and elongation properties. Complementing this, our wax dispersions deliver outstanding surface effects, including enhanced scratch resistance, rubber resistance, and water repellency. Together, these technologies enable the development of high-performance, sustainable coatings with enhanced durability, aesthetic appeal, and functional benefits. Join us to explore how these advanced solutions are driving innovation in the coatings industry.

Nabil Naouli

Sales Director - Coatings & Packaging for Mitsui Chemical America

Innovative Polyurethane and Wax Dispersions Technologies for High-Performance Coatings

Nick Penrose is the End Use Specialist for Wood Coatings at and has been with BYK USA, Inc. for three years. Nick has been involved in multiple roles through the CASE market since 2012, where he has both process, R&D and Innovations experience.

A thorough investigation into the needs of the wood coatings market revealed significant gaps in two key areas: (1) wetting and dispersing agents capable of stabilizing colors and pigments to meet industry color requirements and, (2) a regulatory compliant product that efficiently disperses matting agents without increasing low-shear viscosity for matte coatings. An ideal solution would need to be a 100% active additive, effective in both water-based and solvent-based systems and suitable for use as both a grind and post-add additive.

In response to these challenges, a newly developed novel polyurethane-based wetting and dispersing agent has successfully addressed these needs. Comprehensive studies in various wood coatings have demonstrated that this versatile additive enhances color stability in both in-house and commercial pigment concentrates for both water-based and solvent-based coatings, offering improved anti-settling properties and superior color control. Additionally, it delivers competitive performance against industry-leading wetting and dispersing agents for matting clear coats while maintaining compliance with regulatory requirements.

Nick Penrose

End Use Specialist – Wood Coatings, BYK USA, Inc.

Novel Polyurethane Wetting and Dispersing Additive for Color Stability and Matting Agents for Wood Coatings

Dr. Otto Soidinsalo holds a Ph.D. in organic chemistry from the University of Helsinki and works as Business Development Manager at Borregaard. Before joining Borregaard, Otto spent several years in various positions ranging from R&D to product and application development and technical services. Currently Otto is focusing on coatings and paper & packaging. Otto possesses a deep understanding of natural polymers and their impact on rheology as well as mechanical properties of various applications.

Waterborne paints are complex systems and finding a good balance in terms of sagging, levelling, spraying and drying can be often challenging, especially in the case of high build coatings. Sagging is driven by the gravitational shear stress whereas levelling is mainly driven by the surface tension. Increasing viscosity and yield stress in order to prevent sagging will hinder the levelling. On top of that, increasing the wet film thickness will often lead to mud-cracking.

Microfibrillated cellulose (MFC), is 100% biobased, multifunctional product made of cellulose. MFC is low shear thickener, leading to significant increase in the low shear viscosity with minimal impact on mid shear (KU) and with no impact on the high shear (ICI). Addition of MFC to the paint formulation reduces significantly the tendency for sagging. The low molecular extensibility, enables good sprayability of the formulation. In addition, MFC shortens the drying time of the coating, prevents mud cracking and improves the final properties of the coating

In this work, the effect of MFC on drying speed was studied with two high build waterborne formulations; An insulation coating based on 100% acrylic binder and a basement coating based on acrylic copolymer binder. We will demonstrate how MFC shortens the drying time of coatings, compared to traditional thickeners commonly used. The formulations were evaluated in terms of rheology, sag resistance, mud-cracking, water absorption, strength and drying speed.

Otto Soidinsalo

Business Development Manager, Borregaard

Improved applicability and faster drying of high build waterborne coatings with micro fibrillated cellulose